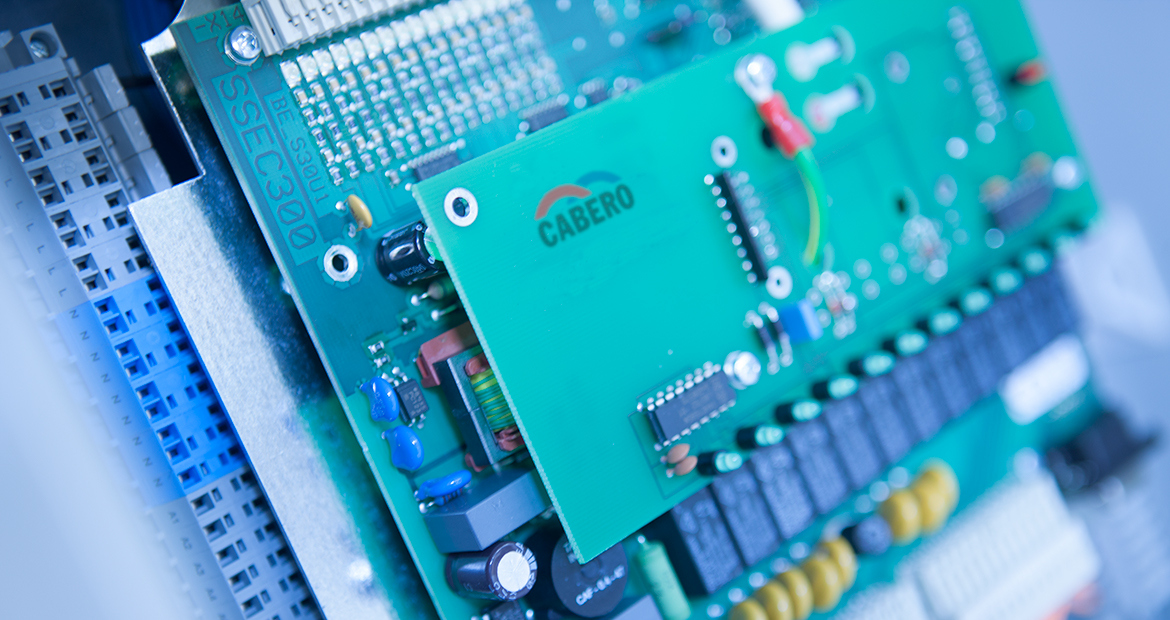

Control technology

The CABERO control technology is modular in design and offers the customer everything from the simple small cabinet from the series to the completely individual solution with customer-specific software.

High-quality technology for the "low budget" Tariff:

CABERO CMM for controlling the EC fansOptimal for the control and regulation of our dry coolers and axial condensers in the different designs. A clear, understandable menu navigation is provided, which makes the user understand the entries and messages clearly. Even in this variant, they have decisive advantages and a multitude of connectivity options:

The inputs and outputs are programmable so that a variety of functions can be assigned to the inputs and outputs, such as:

Interface: MODBUS RTU

CABERO EC-LOG / ADILOG Control of adiabatic and EC fans

Optimal for the control and regulation of our dry coolers and axial condensers with adiabatic spraying in the LPSS and HPSS version. Here, too, a clear, understandable menu navigation is set, which clearly displays the entries and messages to the user. In this variant, too, they have decisive advantages and a large number of interconnection possibilities.

The following inputs and outputs are available:Interface: Modbus TCP IPCABERO CONTROLLING TECHNOLOGY for technically sophisticated requirements in the field of adiabatic, hybrid and DUO technology:

These coltrols offer the features as before, plus many other important features which are indispensable for the operation of high-quality technology:

Both regulations have the option to connect via VPN. This makes it possible to control and control via a tablet or smartphone.

Here, the user with the CABERO Connect app, the display of the plant 1: 1 on its display, has all operating and error messages

Recognize and adjust settings of the plant, from anywhere in this world.

Both regulations have an alarm and operating archive with which the operating conditions can still be understood after months.

Each operating message and every fault message is recorded in the incoming and outgoing mode. In addition, these control modules have a USB port. After inserting a USB mass storage device, all operating data are automatically recorded. All temperature sensors, Pressure sensors and control sections are recorded and stored continuously with a fixed scale. Already a 4GB USB pendrive allows the recording of more than 8 years. This is stored monthly in a separate file. This allows trends to be recorded over a period of years.

Nearly all common interfaces to building technology can be realized as an option.

We have the solution to your control task in every area of the cooling and liquefaction technology.

Many references and years of experience, give you the security to work with the right partner in this field.